-

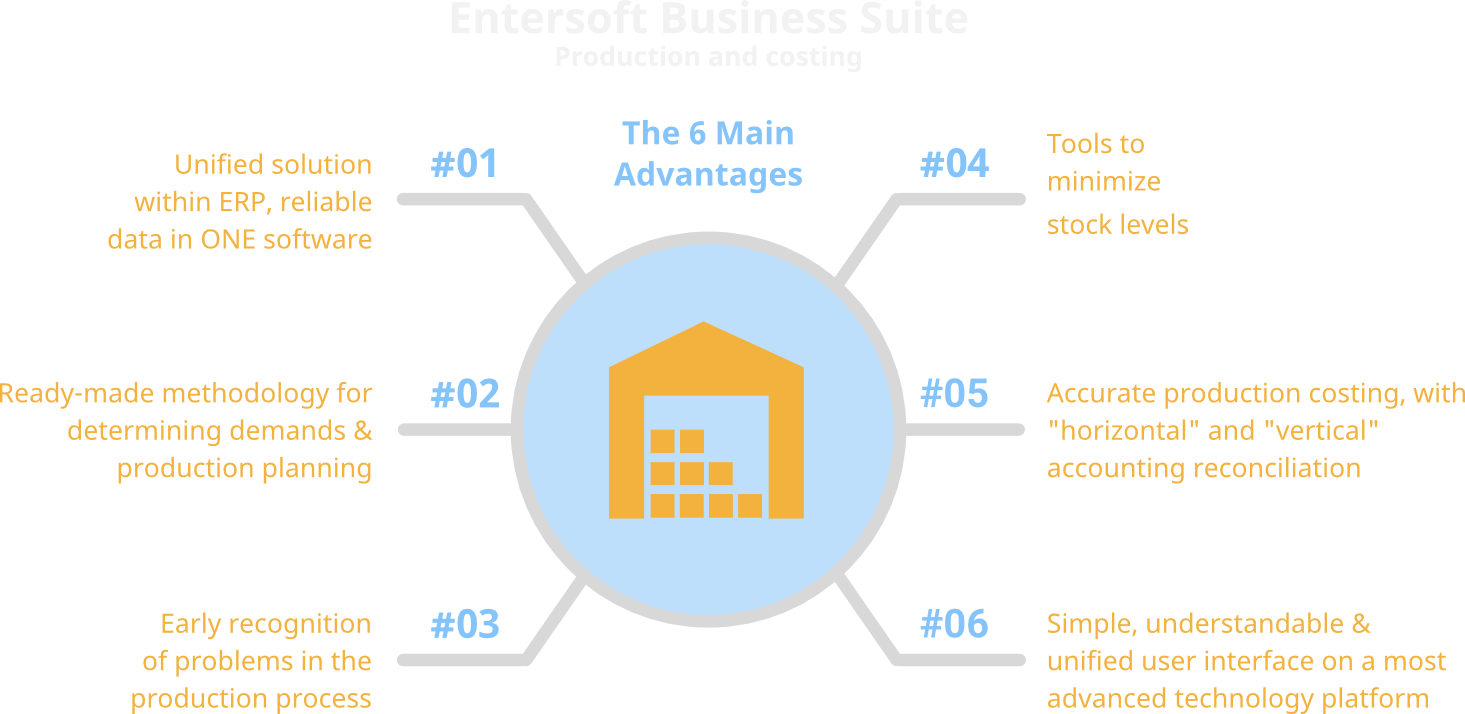

The complete solution

for ManufacturingMonitor and automate

the entire manufacturing process

with Entersoft Business Suite

-

Transparency and control in the manufacturing process

Efficient use of resources: raw materials, machinery, human resources

Advanced production planning (MRPI, MRPII))

360 degree shop floor visibility and control

Optimizing stock levels and avoiding overstocking

Quality

control

of production

Accuracy of production costs and profitability

Seamless integration with suppliers and partners

Reporting and analytics for real-time production monitoring

-

“The integration of modern technologies has led Rolco to a change in the philosophy of the company's operation, with immediate noticeable results in the corporate culture by promoting digital maturity and modernizing its infrastructure. The success of our partnership with Entersoft and its partner Alpha Consultants was the result of hard work, perseverance, mutual support and inspiration by having a common vision, and for us this is a unique recipe for success. The management and staff supported this project, which was so important for Rolco, and adopted the new advanced Entersoft solutions, the results of which everyone currently enjoys, fully realizing that the extensibility of the structure of the new innovative systems is closely linked to the evolution of the company itself. This particular choice proved us right, as the modern ecosystem we received has exceeded our initial expectations, has the appropriate structure to support needs that arose during the implementation process and has laid the foundation for the company's future growth plans”

Garyfalia Vossou - IT Manager, Rolco

-

“At Ioniki we believe that the information system is the backbone of a business.

For this reason, we detected the need for an integrated and extendable solution based on modern technologies, which would help us strategically plan our next steps in the market. Entersoft responded to our trust and demands and joined us in a bold venture for the company, where the coexistence of implementation teams gave a unique result, bravely supporting every decision of Ioniki, without affecting at all the simultaneous operation of the company and its stores. We now have a reliable tool that has helped us upgrade our infrastructure and move into the digital age with a view to the evolution of Ioniki in modern business.”

Yiannis Vacharoglou - Chief Operating Officer, Ioniki

-

“The upgrade of infrastructure that enhances the efficiency and cooperation of the Group's executives in all countries we operate, was the main reason for our decision to proceed with such an important reorganization project. When the moment came for the company to "see" itself as a Group, harmonize the operation with its vision and help the new generation of Management unite the old with the new way of management, it trusted Entersoft to participate in this strategic step of digital transformation, incorporating innovative solutions, which improved our daily life and contributed to the evolution of the EUREKA Group.”

Costas Kourkoumpas - Financial Manager, EUREKA

-

Functionalities

Manufacturing

process

data▷ Hierarchical technical specifications, Routing operations in production, Minimum production package - production lot, alternative materials, matching of materials and products by colors, sizes and quantities

▷ Production units, work resources, operating times, transit times to destination

MPS: Manufacturing

planning

system▷ Medium-term planning based on orders, required, storage needs (days of sufficient stock) - the ability to intervene in the automatically generated production calendar

▷ Create production orders either one by one or in bulk

MRP: Replenishment of materials according to the Production Plan

▷ Automatic calculation of raw material requirements and timely placement of automatically generated purchase orders to ensure the minimum required stock level

▷ Avoiding overstocking

Initiating and monitoring

the production process

▷ Raw material correlation

▷ Bill of Material (BOM)

▷ Calculation of material consumption based on the need, after checking the stocks in the production area

▷ Automatic tool for allocating physical inventory differences to (potential) consumptions already recorded (ie calculated according to material lists)

▷ The outsourcing process

▷ Batch traceability: the complete history, starting from receipt or production to the last delivery. Information about the route and current location of the batch

▷ Execution, monitoring, documentation production process

Overview

of production costs▷ Simple, but complex, rules of cost allocation

▷ Detailed cost drivers for each record in production

▷ Comparison of estimated costs vs. actual costs

▷ Tools to justify the resulting production costs

▷Production costs. What-if scenarios for analyzing the production costs of finished products, for use in trade agreements (discounts) or for developing pricing policy for items to be produced Quality

Quality

control

▷ Defining quality standards, acceptable measurement limits and other control specifications

▷ It relates to products, raw materials, production phases

▷ Quantity reservation for quality control per item and lot (batch)

▷ Recording of measurements, selection of final measurement per check

▷ Release process under conditions of successful control

▷ Quality documents that accompany the product Maintenance

Maintenance

of equipment

and machinery▷ Specifications - component specifications, spare parts and tools, task specifications, risks, forms and documents, counters

▷ Planning - create and assign tasks, alerts for overdue tasks, planning required components, potential risks and preventive measures on scheduled work, measurements to take, forms to fill

▷ Maintenance functions - entering tasks, working hours, consumption - updating stocks, contact notes, interface with the purchasing department, fault management KPIs

KPIs

of the manufacturing

process▷ Average time to complete production orders, lead time for made-to-order products, cost and profitability information

▷ Analysis of costs by production operations, by product or group of products and type of costs

-

Case Studies

Entersoft solutions support Pain Plaisir, the Parisian-inspired artisanal bakery in Bucharest, with its expansion plansSoluțiile Entersoft - instrumentele care ajută Update Advertising să crească și să evolueze continuuGrantex implemented the combined solutions of Entersoft ERP, Entersoft WMS and Production Cycle, in a fully integrated systemRolco has digitalized all production units with Entersoft Business Suite® software solutions (ERP, WMS and Mobile CRM/SFA)Nordia SA integrates digital transformation through Entersoft's innovative and modern models that upgraded its internal infrastructureKonstantinidis Confectioneries has achieved continuous efficiency improvement with the help of Entersoft Business SuiteAlchimica is proceeding to an entire integration of procedures and in real time data exploitation with Entersoft Business Suite